When it comes to constructing a metal roof, it’s important to determine the quantity of materials needed. Calculating the correct quantity of roof sheeting impacts the efficiency and cost-effectiveness of your project.

It may seem difficult at first, but remember that you don’t need a precise measurement. You just need to estimate the number of roof sheets needed, so you have a rough figure of how much your new roof will cost.

In this guide, we’ll walk you through the process of measuring the number of metal sheets needed for your roof. No need for guesswork and overestimation, which can lead to the wastage of resources and budgetary concerns. You’ll be equipped to assess your project’s scope and accurately determine the number of sheets necessary.

1. Understand Your Roof’s Dimensions

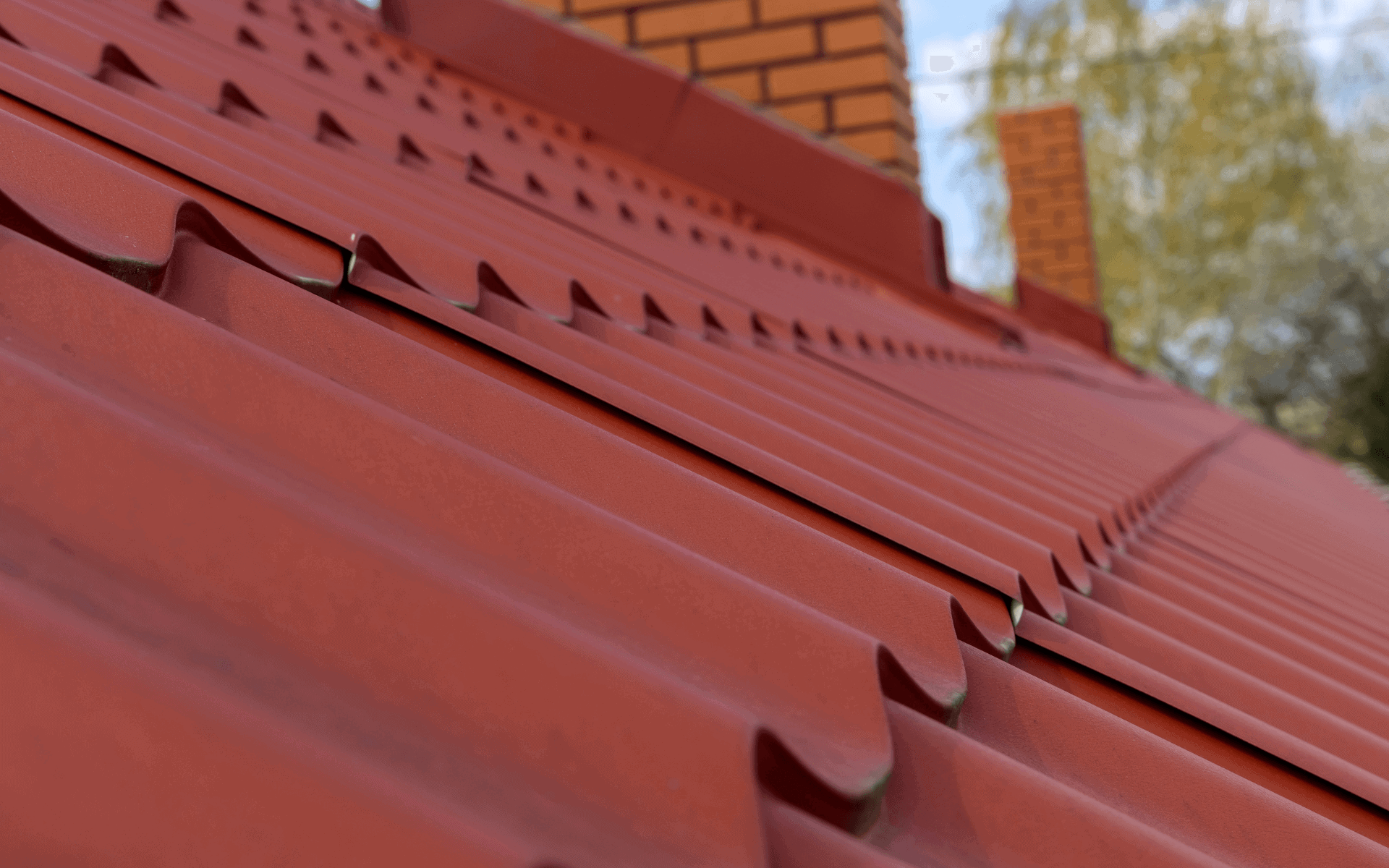

Accurate measurements begin with a clear understanding of your roof’s design and dimensions. It’s helpful to sketch a rough outline of your roof to help visualise your measurements. Start by measuring the length and width of the roof from the ground. If the roof is complex, break it down into smaller sections and measure each separately. Make sure you have an understanding of the metal roof sheet dimensions and profiles you plan to use.

2. Calculate Roof Area

To calculate the total roof area, multiply the length by the width. This will give you the area in square meters. Roof overhangs or slopes will impact the amount of metal sheets you require. Measure the area of any overhang and slopes separately and add it to your total roof area.

3. Measure One Metal Sheet Profile

Different metal roofing profiles have varying coverage areas. This information is typically provided by the manufacturer. We provide the dimensions of the roof sheeting products we manufacture on each product page. You can calculate the coverage area of one sheet by multiplying the length by the width.

4. Calculate the Number of Sheets

Divide your total roof area (including overhangs and slopes) by the coverage area of a single metal roof sheet. This figure is the number of sheets needed for your project. Always round up to the nearest whole number to ensure you have enough sheets to cover the entire roof.

Remember to factor in any vents, chimneys or vents in the roofing. It’s also important to account for wastage. This could be due to cuts, errors or future repairs. We typically advise adding 5-10% to your quantity depending on the roof’s complexity and your experience.

5. Double Check and Order

It’s good practice to have a second pair of eyes review your calculations to avoid any potential errors. You should always double-check your calculations to ensure accuracy. Once you’re happy with your calculations, you can place an order for your roof sheeting.

If you have any further questions about metal roofing, contact Dynamic Steelform. Our team will work with you to find the ideal sheet profile for your project.